MAKCNC Vertical CNC Machining Center MV970 is a small and medium-sized fixed-column vertical machining center,

Vertical CNC Machining Center MV1160 suitable for auto parts processing and other heavy-cut precision industries. processing

Vertical CNC Machining Center MV1270 (VMC1270)is a medium-sized fixed-column vertical machining center, which adopts electromechanical integration design, has a beautiful appearance and can perform precision cutting.

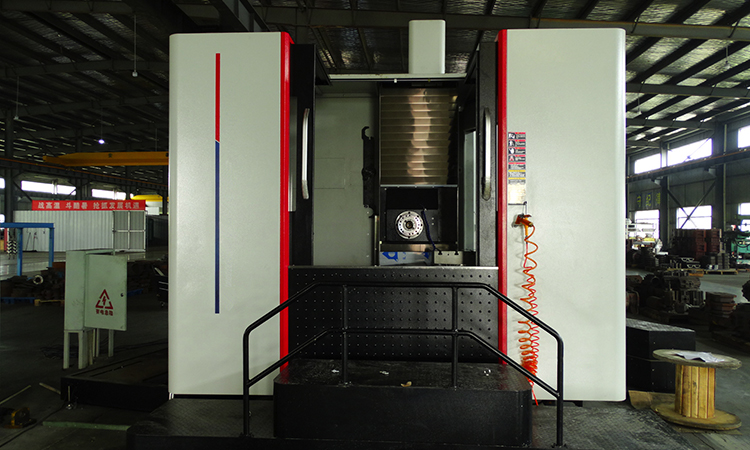

Vertical CNC Machining Center MV1380 is a medium-sized fixed-column vertical machining equipment.

Horizontal CNC machine tools use spindles that operate parallel to the ground, as opposed to vertical machines where the spindle is oriented vertically.

What is CNC Machining Center?

A machining center is a CNC machine tool that can perform different operations like milling, boring, and drilling, with high accuracy and minimal time. It consists of an automatic tool-changing mechanism that enables it to use multiple cutting tools during the machining process.

Features of CNC Machining Center

A basic CNC Machining Center refers to a Computerized Numerically Controlled Milling Machine. This Machining Center will have a minimum of 3 axis, referred to as X, Y, and Z. It will incorporate a milling or drilling type tool mounted in a rotating spindle. The workpiece to be machined will be clamped or fixtured on the X-axis and typically does not rotate. A CNC Machining Center will also include an automatic tool changer versus a basic Milling Machine that utilizes one type of cutting tool that is manually changed.

The rotating spindle is at the heart of every CNC machining center. It is mounted vertically with the spindle head/tool connection pointing down, or horizontally with the spindle head/tool connection pointing forward. The spindle is driven by a belt, coupled directly to a drive motor, or has an integrated motor called an electric spindle. The spindle is the most critical component of the CNC machining center. It controls and ultimately determines the overall geometry and quality of the workpiece.

A CNC machining center with a vertically mounted spindle has the spindle mounted on the Z axis. The Z axis moves up and down. The X axis moves from left to right and fits onto the Y axis. The Y axis moves from front to back. All three axes are independent mechanical units. Precision ball screws controlled by CNC machines move each axis in precise increments.

Applications of CNC Machining Center

CNC Machining Center can perform different operations like milling, boring, and drilling, with high accuracy and minimal time. It consists of an automatic tool-changing mechanism that enables it to use multiple cutting tools during the machining process.

Machining centers have vast industrial applications, commonly employed in power generation, automobile, aerospace, and marine industries.

Mold making

Machining centers are used to make molds, mainly through drilling and milling processes.

These molds are then used to make components such as automobile engines, aircraft sheet metal parts, and other glass and rubber parts.

Complex Components

Due to their ability to produce complex parts with high precision, machining centers are used to manufacture highly complex parts such as wing frames, impellers, propellers, radiators, etc.

Mass Manufacturing

The automated nature of machining centers gives them high repeatability, making them ideal for mass production of identical components such as spur gears.

Suppliers of CNC Machining Center

MAKCNC is a professional CNC Machining Center Manufacturer provides high quality, reliable and cost-effective CNC machining center for global customers, if you are looking for CNC Machining Center, feel free to get a quote.