Description

The horizontal machining center is suitable for complex machining of box-type parts. During the machining process, the tool can be automatically exchanged, and it can be clamped for four-sided milling, drilling, reaming, boring, reaming, tapping, Modern machine tools and control concepts, compact structure design, ensure high efficiency and high precision processing requirements for single piece or small and medium batch products.

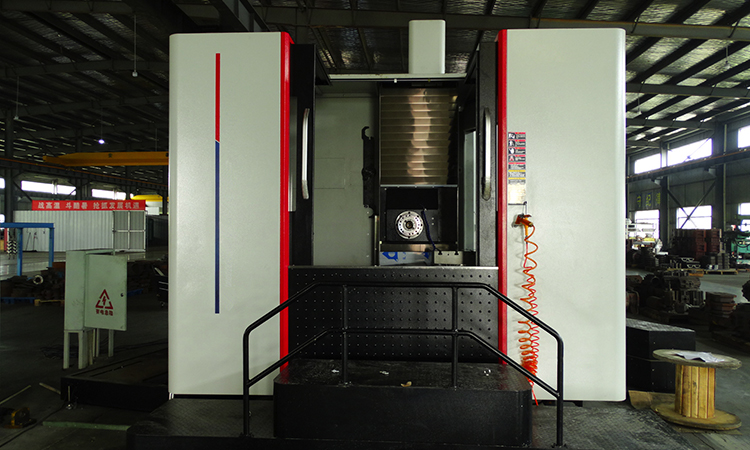

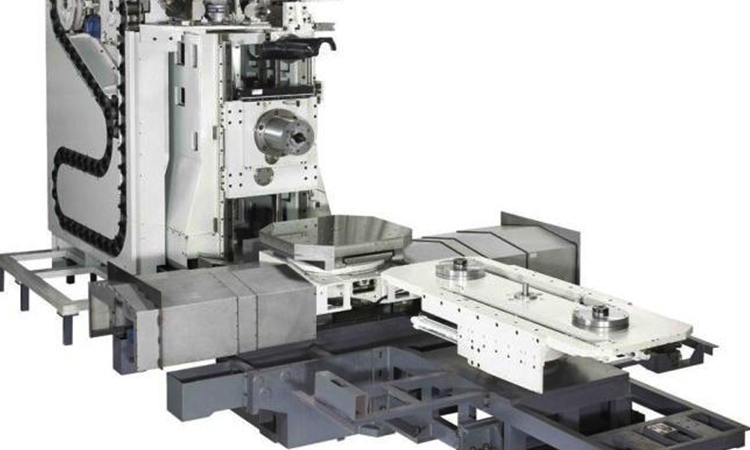

Whole machine: The main structure of the machine tool is an inverted T-shaped, full-moving column structure with good rigidity. There is no distortion or bending deformation when the room temperature changes, and stable high precision is maintained. The whole machine fully embodies the engineering concept of human-machine integration. It is a high-end CNC machine tool with high performance, high efficiency and high speed, and is easy to use, operate and maintain.

Base: The advanced finite element analysis software ANSYS is used to rationally optimize the layout of double-shaped ribs to ensure its strength and rigidity, so that the performance indicators of each component are optimal, and the stability of precision is guaranteed.

Column: Double structure column, with high torsional and bending rigidity and left-right symmetrical structure, ensures excellent thermal stability.

Headstock: The AC servo spindle motor can realize stepless speed regulation of the spindle, and at the same time meet the requirements of low speed, high torque and high-speed cutting.

Drive: The advanced large inertia feed servo motor is selected to realize the three-axis feed drive, and the Taiwan high rigidity ball screw is used. The X/Y/Z axis is a wire gauge structure and adopts a roller guide rail, which has good stability and high precision.

System configuration: Equipped with high-performance FANUC CNC system, which can guarantee the CNC machining functions and auxiliary functions required by users.

Optional configuration: Optional spindle center water outlet (other accessories such as center outlet water pump and other connection accessories need to be purchased separately) to realize tool center water outlet cooling and chip removal.

The processing and assembly quality of all parts of the machine tool conforms to the product drawings and related technical requirements, its safety standard conforms to the relevant provisions of GB15760-2004 "General Technical Conditions for Safety Protection of Metal Cutting Machine Tools", and its precision standard conforms to GB/T17421-2000 "General Rules for Inspection of Machine Tools "And the relevant provisions of JB/T8771-1998 "Inspection Conditions for Machining Centers".

Specification

MH- 5 00 basic parameters

name | unit | parameter | Remark | |

processing scope | X/Y/Z axis travel | mm | 800/800/800 | |

Spindle center to table surface | mm | 0-800 | ||

Spindle nose to table center | mm | 220-1020 | ||

work do tower | Workbench area | mm | 500×500 | |

workpiece size | mm | Φ700 | ||

Maximum load of workbench | kg | 1000 | ||

workpiece height | mm | 1000 | ||

Working table minimum split angle | ° | 1° | ||

T-shaped slot ( number of slots x slot width x spacing) | mm | 5×14×100 | ||

host axis | Spindle speed | RPM | 8000 | ring spray |

Maximum processing size (rotation diameter) | mm | 1200 | ||

Spindle taper | BT | BT40 | ||

Spindle Maximum Cutting Torque (Standard) | N m | 105 | ||

Spindle motor (rated/maximum) | k | 11/15 | ||

speed Spend | Three-axis rapid displacement speed (x/y/z) | m/min | 36/36/36 | |

The minimum setting unit of the machine tool | 0.001 | |||

knife library | Shank form | BT | BT-40 | |

Number of tools | Only | 24/optional 30 | ||

tool diameter/length/weight | Φ120mm/300mm/8kg | |||

Maximum tool diameter (adjacent without tools) | mm | 120 | ||

Tool selection method | optional | |||

Tool change time | S | 2.33/4.75 | ||

machine bed Refined Spend | Positioning accuracy (x/y/z) | mm | VDI0.008 | |

Repeat positioning accuracy (x/y/z) | mm | VDI0.005 | ||

Indexing accuracy of rotary table | " | ±5″sec | ||

Rotary work repeat indexing accuracy | " | ±2″sec | ||

That it | barometric pressure | Kg/bar | 6-8 | |

Cutting fluid tank volume | L | 300 | ||

Main motor model | β ilP 18 /6000 | |||

electricity demand | KVA | 50 | ||

Four axis motor model | β22/β22B/β22/β12 | |||

Three-axis lead screw model | R4012 | |||

Three axis gauge model | RGH45 | |||

Machine tool standard configuration

serial number | name | quantity | Remark |

1 | Fully enclosed guard | 1 | |

2 | CNC system | 1 | FANUC MF5 PLUS |

3 | Handheld operating unit | 1 | |

4 | Disc magazine | 1 | twenty four |

5 | Automatic chip removal device | 5 | Chain plate chip remover * 1 ; spiral pin remover 4 |

6 | automatic lubrication system | 1 | |

7 | Three-color light | 1 | |

8 | Hydraulic system | 1 | |

9 | air curtain protection | 1 | |

10 | air gun | 1 | |

11 | lighting device | 1 | |

12 | Random set of standard technical documents | 2 | Hard copy documents |

Equipment main parts brand

serial number | Name and specification | brand | Remark |

1 | Control System | FANUC | Japan |

2 | Spindle unit BT40 | Onari | Taiwan |

3 | Spindle bearing | NSK | Japan |

4 | Spindle speed change | 1 :1 | - |

5 | Screw bearing | NSK | Japan |

6 | ball screw | HIWIN /PMI | Taiwan |

7 | Linear Guides | HIWIN /PMI | Taiwan |

8 | Disc magazine | Zongxin | China |

9 | Rotary table | 1/360° | Taiwan |

10 | lubrication system | Proton /Bachel | China |

11 | Hydraulic system | Germin | zhejiang |

12 | Electrical cabinet air conditioner | Fly together | three rivers |

13 | main electrical components | Schneider | France |

Note: The manufacturer reserves the right to replace the same brand

Standard Technical Documents (Paper Documents)

serial number | Name and specification | quantity | Remark |

1 | Packing List | 1 | Provide paper documents only |

2 | Certificate of Compliance | 1 | Provide paper documents only |

3 | CNC system operation manual | 1 | Provide paper files + CD |

4 | foundation drawing, outline drawing | 1 | If necessary , provide within 1 month after signing the contract |