Description

MV 1 1 60 is a medium-sized fixed-column vertical machining equipment, which not only satisfies drilling and tapping, but also meets various cutting plane milling processes. It is suitable for auto parts processing and other heavy-cut precision industries. processing. This model is equipped with a BT40 spindle, which can meet certain heavy cutting requirements. At the same time, it has the dual advantages of three-axis heavy load of the machine tool. After the workpiece is clamped once, the machine tool can automatically and continuously complete milling, drilling, boring, expanding, reaming, countersinking, and tapping. Processing of various processes such as silk, etc. After the optional CNC rotary table is added, 4- axis/ 5- axis processing of complex parts can be performed.

This machine is suitable for multi-variety processing of complex parts such as medium and small boxes, plates,discs, shells, etc. It is widely used in auto parts, molds, valves, construction machinery, IT equipment, optical equipment, medical equipment and aerospace industries.

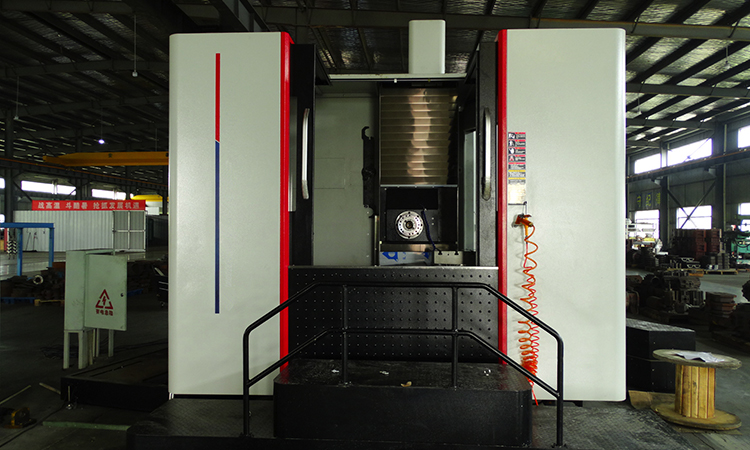

Whole machine: The whole machine is fixed by a column, which adopts a "herringbone"-shaped large-spanstructure, so that the overall coordination and stability of the bed body achieves high rigidity and stability, thereby ensuring the high performance and high precision of the whole machine. Cross slide moving structure. The whole machine has high rigidity, high stability and high reliability, fully enclosed protection, beautifulappearance, convenient operation and maintenance.

Spindle box: Taiwan spindle unit is adopted , and the maximum spindle speed can reach 8000rpm/min.

Drive: The three-axis motor is connected to a high-precision ball screw, and the three-axis transmission is stable. The ball screw is pre-stretched and installed to further improve the transmission rigidity and positioning accuracy. The three linear coordinate axes all adopt heavy-duty linear guide rails. The vibration of the machine tool is small when it is fed at high speed, and there is no crawling when it is fed at low speed , and it has high precision and stability.

System: Equipped with high-performance Japanese FANUC system, which ensures the long-term stability of the machine tool control, and also guarantees the general function and auxiliary function of CNC machining required by users .

Tool magazine: BT40 disc manipulator tool magazine is adopted , with reliable quality and stable performance . The tool magazine adopts manipulator to change the tool, the capacity of the tool magazine is 24 knives , and the tool changing time is fast.

The quality of all parts and components of machine tool processing and assembly conforms to the product drawings and related technical requirements, its safety standard conforms to the relevant provisions of GB15760-2004 "General Technical Conditions for Safety Protection of Metal Cutting Machine Tools", and its precision standard conforms to GB/T17421-2000 "Machine Tool Inspection "General Rules" and JB/T8771-1998 " Machining Center Inspection Conditions " related regulations .

Advantages of VMC1160 Vertical Machining Center

◆The three-axis adopts linear slide rail, or two-line and one hard guide rail, which has high rigidity, high positioning, low noise and low friction characteristics, and can do rapid displacement (36m/min) and better circular accuracy;

◆The main structural castings are made of high-strength Meehanite cast iron, which has a stable structure and stable quality;

◆Castings are calculated and analyzed by computer with finite element analysis method, reasonable structural strength and matching of reinforcing ribs provide high rigidity and stability of machinery;

◆The wide base and column are both box-shaped structures, the saddle is widened and lengthened, and the heavy-duty full-support design has a solid structure, which can ensure the heavy-duty capacity during processing;

◆The structure of the spindle head is strengthened with bones, and the ratio of the contact length between the spindle head and the column is appropriate to provide a stable support for the spindle;

◆The machine is equipped with an anti-collision device, which can absorb the vibration caused by the impact caused by the worker's operation error, so as to minimize the damage of the impact and ensure the original accuracy;

◆The machine adopts an oil-water separation design, which can effectively separate the lubricating oil from the cutting fluid, preventing the cutting fluid from deteriorating due to mixing and affecting the processing quality;

◆The machine adopts high-rigidity and high-precision spindle of Taiwan brand, the belt-type spindle has strong rigidity and high reliability, and the direct-connected spindle has high speed and high precision, low noise and low vibration, fully meeting the needs of users;

Description of functions and features of VMC1160 vertical CNC machining center

General layout of VMC1160 machine tool

The VMC1160 vertical machining center adopts a vertical frame layout, the column is fixed on the main body, the spindle box moves up and down along the column (Z direction), the slide seat moves longitudinally along the bed (Y direction), and the worktable moves laterally along the slide seat (X direction). to) structure.

The main body, workbench, sliding seat, column, headstock and other large parts are all made of high-strength cast iron materials. These large parts are assisted by three-dimensional computer software to optimize the design. The whole machine has sufficient strength, rigidity and high stability.

CNC system of VMC1160

The CNC system is equipped with KND2000 or Guangshu 25i control system and drive as standard, with complete functions and easy operation; standard RS-232 communication interface, USB socket and related software, with DNC online processing function.

Drag system of VMC1160

The X, Y, and Z-axis guide rail pairs adopt Taiwan Shangyin 45mm rolling linear roller guide rail, which has small dynamic and static friction, low wear, high positioning accuracy, high sensitivity, small high-speed vibration, long service life, interchangeability, and excellent servo drive performance. , Improve the accuracy and accuracy stability of the machine tool.

The X, Y, and Z axis servo motors are directly connected to Taiwan's high-precision ball screws through elastic couplings, reducing intermediate links, realizing gapless transmission, flexible feeding, accurate positioning, and high transmission precision.

The Z-axis servo motor has an automatic brake function. In the event of a power failure, the automatic brake can hold the motor shaft tightly so that it cannot rotate, which plays a role of safety protection.

Spindle group of VMC1160

The spindle group adopts Taiwan Jianchun spindle, the speed is 8000rpm, and the outer diameter is 150mm. The machine has high precision and high rigidity. The bearings are NSK bearings specially used for P4 spindles. After the entire set of spindles are assembled under constant temperature conditions, they pass the dynamic balance correction and running-in test, which improves the service life and reliability of the entire set of spindles.

The spindle can realize stepless speed regulation within its speed range, and the spindle is controlled by the built-in encoder of the motor, which can realize the functions of spindle orientation and rigid tapping.

Tool magazine for VMC1160

Taiwan Desu disc 24 tool magazines are used, which are installed on the side of the column. When the tool is changed, the cutter head is pushed by the cylinder to move left and right. The cylinder is equipped with a proximity switch to ensure that the tool change position is accurate. After the cutter head reaches the tool change position, the spindle moves up and down. Returning and grabbing the knife, the process of changing the knife is simple and reliable.

Cutting Cooling System of VMC1160

Equipped with a large-flow cooling pump and a large-capacity water tank to fully ensure circulating cooling, the power of the cooling pump is 450W, and the large-flow cooling pump of 28L/min provides sufficient cooling.

The end face of the spindle box is equipped with cooling nozzles, which can be either water-cooled or air-cooled, and can be switched at will.

Equipped with a cleaning air gun to clean the machine tool.

Pneumatic system of VMC1160

Pneumatic triplex can filter impurities and moisture in the air source, preventing impure gas from damaging and corroding machine tool components. The solenoid valve group is controlled by the PLC program to ensure that the actions of spindle tool loosening, spindle center blowing, spindle clamping, and spindle air cooling can be completed quickly and accurately.

Protection of VMC1160

VMC1160 adopts a protective room that meets safety standards, which not only prevents coolant from splashing, but also ensures safe operation and a pleasant appearance. Each guide rail of VMC1160 has a protective cover to prevent chips and coolant from entering the machine tool, and protect guide rails and ball screws from wear and corrosion.

Lubrication system of VMC1160

The guide rail and the ball screw pair are all lubricated by central centralized automatic thin oil, and each node is equipped with a quantitative oil separator, which injects oil to each lubricating part regularly and quantitatively to ensure that the sliding surfaces are evenly lubricated, effectively reducing frictional resistance and improving motion. The precision ensures the service life of the ball screw pair and the guide rail.

Chip removal system for VMC1160 (optional)

The iron filings generated during the processing fall directly on the guard room, and the internal slope structure of the guard makes the iron filings slide down smoothly into the chip discharge groove, and then taken out through the drawer.

Working conditions of VMC1160

(1) Power supply: 380V±10% 50HZ±1% three-phase AC

(2) Operating temperature: 5°C-40°C

(3) The best ambient temperature: 15°C-25°C

(4) Relative humidity: 40-75%

(5) Air source pressure: 0.5-0.7Mpa

Specification

Basic parameters

name | unit | parameter | Remark | |

processing scope | Table X-axis travel | mm | 1100 | |

Table Y-axis travel | mm | 600 | ||

Worktable Z-axis travel | mm | 600 | ||

Distance from spindle nose to table centerline | mm | 120-720 | ||

from spindle centerline to column guide rail surface | mm | 760 | ||

work do tower | working desk size | mm | 1200x600 | |

maximum load | kg | 1000 | ||

T-slot ( slot width x number of slots x spacing) | mm× unit ×mm | 18×7×90 | ||

X, Y, Z axis rapid feed | m/min | 36x36x24 | ||

knife library | Disc tool magazine - number of tools | T T | 24T | |

tool diameter/length/weight | φ78mm/300mm/8kg | |||

Maximum tool diameter (adjacent without tools) | mm | φ120 | ||

Tool selection method | optional | |||

Tool exchange time (knife-knife) | S | 1.78 | ||

host axis | Spindle speed | rpm | 0-8000 | ring spray |

Spindle taper | BT | BT40 | ||

Spindle motor power (rated/maximum) | kw | 11 / 15KW | ||

Triaxial power | kw | 3-3-3 | ||

machine bed Refined Spend | Positioning accuracy (X/Y/Z) | mm | VDI0.008 | |

Repeat positioning accuracy (X/Y/Z) | mm | VDI0.005 | ||

X/Y/Z axis track number | 2/2/2 | 2/2/2 | ||

Maximum Tapping Diameter | mm | M24 | ||

Maximum drilling diameter | mm | φ45 | ||

Milling capacity | cm³/min | 260 | ||

electricity demand | KVA | 20 | ||

Cooling box volume | L | 160 | ||

barometric pressure | Kg/bar | 6-8 | ||

Gas source | L/min | 280 | ||

Three axis gauge model | 45-45-45 | |||

Machine tool standard configuration

serial number | name | quantity | Remark |

1 | Fully enclosed guard | 1 | |

2 | CNC system | 1 | FANUC |

3 | Tool magazine | 1 | 24 |

4 | automatic lubrication system | 1 | |

5 | Cooling water pump | 1 | |

6 | Three-color light | 1 | |

7 | Spindle blowing device | 1 | |

8 | air curtain protection | 1 | |

9 | cleaning air gun | 1 | |

10 | lighting device | 1 | |

11 | Electric cabinet heat exchanger | 1 | |

12 | Random accessories | 1 |

Equipment main parts brand

serial number | Name and specification | brand | Remark |

1 | Control System | FANUC | Japan |

2 | Spindle unit | Yu Cheng / Jian Chun | Taiwan |

3 | Spindle bearing | NSK /KOYO | Japan |

4 | Screw bearing | NSK /KOYO | Japan |

5 | ball screw | HIWIN /PMI | Taiwan |

6 | Linear Guides | HIWIN /PMI | Taiwan |

7 | Tool magazine | Shanghai Zongxin | China |

8 | lubrication system | Proton /Bachel | China |

9 | heat exchanger | Tongfei/ Diot | China |

10 | main electrical components | Schneider | France |

Note: The manufacturer reserves the right to replace the same brand