Description

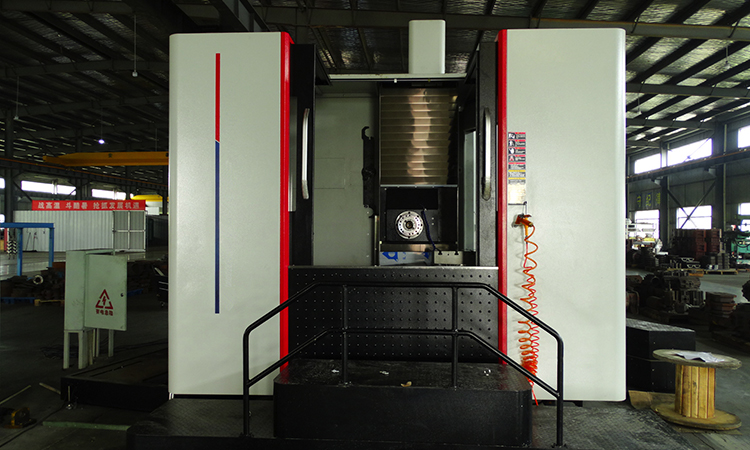

MV1270(VMC1270) is a medium-sized fixed-column vertical machining center, which adopts electromechanical integration design, has a beautiful appearance and can perform precision cutting. After the workpiece is clamped once, the machine tool can automatically and continuously complete various processes such as milling, drilling, boring, expanding, reaming, countersinking, and tapping.

This machine is suitable for multi-variety processing of complex parts such as medium and small boxes, plates, discs, shells, etc. It is widely used in auto parts, valves, engineering machinery, IT equipment, optical equipment, medical equipment and aviation Aerospace and other industries.

All Machine:The whole machine is fixed by columns, and the structure of cross sliding table is movable. The whole machine has high rigidity, high stability and high reliability

sex. The machine tool has the function of chip flushing with large flow . The fully enclosed protection has a beautiful appearance and is easy to operate and maintain.

Spindle box: Taiwan 's high-speed spindle is adopted, and the spindle adopts BT40 specification.

Tool magazine: The tool magazine adopts a disc-type tool magazine with reliable quality and stable performance .

Drive: The three-axis motor and the high-precision ball screw are directly connected and driven. The ball screw is pre-stretched and installed to further improve the transmission rigidity and positioning accuracy. The three linear coordinate axes all adopt linear roller guideways.

System: Equipped with high-performance Japanese FANUC CNC system, which ensures the stability of the machine tool control, and also guarantees the CNC processing functions and auxiliary functions required by users.

The quality of all parts and components of machine tool processing and assembly conforms to the product drawings and related technical requirements, and its safety standard conforms to the relevant provisions of GB15760-2004 "General Technical Conditions for Safety Protection of Metal Cutting Machine Tools", and its precision standard conforms to GB/T17421-2000 "Machine Tool Inspection "General Rules" and JB/T8771-1998 " Machining Center Inspection Conditions " related regulations.

Features of Vertical CNC Machining Center VMC1270

Vertical CNC machining center VMC1270 has high-speed and efficient cutting performance:

1. The structure of the whole machine is a fixed column type and a cross slide structure. The fuselage adopts a super large and stable base, and a high-rigidity large-span herringbone column with small deformation during high-speed cutting;

2. The spindle adopts a high-speed and high-precision spindle unit. The front end of the spindle adopts a labyrinth design with an air curtain protection function and a circulating cooling device, which makes the spindle temperature rise small, thermal deformation small, and high processing accuracy;

3. The three-axis guide rail adopts high rigidity line rail bearing, low friction and low noise;

4. The standard configuration of the machine tool is equipped with rear flushing and chip removal, and the rear design of the water tank is automatic, user-friendly and high-efficiency. The labyrinth water tank filter system structure provides good cutting fluid for workpiece processing.

5. Equipped with a high-performance CNC system, which ensures the stability of the machine tool control, and has superior CNC processing functions and auxiliary functions.

Application field of vertical CNC machining center VMC1270

VMC1270 is suitable for small and medium-sized batch processing of various complex parts such as small and medium-sized boxes, plates, discs, valves, shells, molds, etc. It is widely used in precision parts, 5G products, hardware, auto parts, and medical equipment industries.

Specification

Machine parameters and configuration

Basic parameters

name | unit | parameter | Remark | |

processing scope | Table X-axis travel | mm | 1200 | |

Table Y-axis travel | mm | 700 | ||

Worktable Z-axis travel | mm | 700 | ||

Distance from spindle nose to table centerline | mm | 170-870 (short nose end) | 150-850 (long nose end) | |

from spindle centerline to column guide rail surface | mm | 760 | ||

work do tower | working desk size | mm | 1300×700 | |

maximum load | kg | 1050 | ||

T-slot ( slot width x number of slots x spacing) | mm× unit ×mm | 18×7×90 | ||

X, Y, Z axis rapid feed | m/min | 36×36× 24 | ||

knife library | Disc tool magazine - number of tools | T T | 24T | |

tool diameter/length/weight | φ78mm/300mm/8kg | |||

Maximum tool diameter (adjacent without tools) | mm | φ120 | ||

Tool selection method | optional | |||

Tool exchange time (knife-knife) | S | 1.78 | ||

host axis | Spindle speed | rpm | 0-8000 | ring spray |

Spindle taper | BT | BT40 | ||

Spindle motor power (rated/maximum) | kw | 11KW/15KW | ||

Triaxial power | kw | 3-3-3 | ||

machine bed Refined Spend | Positioning accuracy (X/Y/Z) | mm | VDI0.008 | |

Repeat positioning accuracy (X/Y/Z) | mm | VDI0.005 | ||

X/Y/Z axis track number | 45/55/45 | 2/2/2 | ||

Maximum Tapping Diameter | mm | M24 | ||

Maximum drilling diameter | mm | φ45 | ||

Milling capacity | cm³/min | 260 | ||

electricity demand | KVA | 20 | ||

Cooling box volume | L | 200 | ||

barometric pressure | Kg/bar | 6-8 | ||

Gas source | L/min | 280 | ||

Machine tool standard configuration

serial number | name | quantity | Remark |

1 | Fully enclosed guard | 1 | |

2 | CNC system | 1 | FANUC |

3 | Tool magazine | 1 | 24 |

4 | automatic lubrication system | 1 | |

5 | Cooling water pump | 1 | |

6 | Three-color light | 1 | |

7 | Spindle blowing device | 1 | |

8 | air curtain protection | 1 | |

9 | lighting device | 1 | |

10 | heat exchanger | 1 | |

11 | Random accessories | 1 |

Standard Technical Documents (Paper Documents)

serial number | Name and specification | quantity | Remark |

1 | Packing List | 1 | Provide paper documents only |

2 | Certificate of Compliance | 1 | Provide paper documents only |

3 | CNC system operation manual | 1 | Provide paper files + CD |

4 | foundation drawing, outline drawing | 1 | If necessary , provide within 1 month after signing the contract |

Equipment main parts brand

serial number | Name and specification | brand | Remark |

1 | Control System | FANUC | Japan |

2 | Spindle unit | Jianchun/Yucheng | Taiwan |

3 | Spindle bearing | KOYO/NSK | Japan |

4 | Screw bearing | KOYO/NSK | Japan |

5 | ball screw | Law Ting / HIWIN /PMI | Taiwan |

6 | Linear Guides | HIWIN /PMI | Taiwan |

7 | Tool magazine | Zongxin | China |

8 | lubrication system | Proton /Bachel | China |

9 | heat exchanger | Diot | China |

10 | main electrical components | Schneider | France |

Note: The manufacturer reserves the right to replace the same brand