Detailed explanation about horizontal machining center

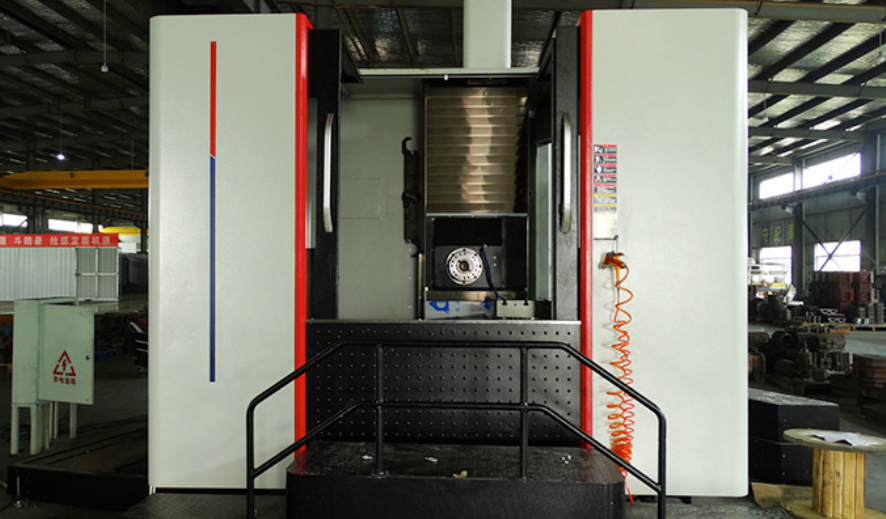

The horizontal CNC machining center refers to the machining center machine tool whose spindle axis is parallel to the worktable. It can process larger parts, and it can also be indexed and rotated. It is most suitable for multi-process processing such as milling, drilling, boring, reaming, tapping, two-dimensional and three-dimensional curved surfaces of parts. It has the ability to complete the box in one clamping It has good performance in body hole system and plane processing, and is especially suitable for turning around the box hole. It is widely used in automobiles, internal combustion engines, aerospace, home appliances, general machinery and other industries.

Horizontal CNC machining centers are divided into fixed column type and mobile column type according to whether the column moves.

Fixed Column Type CNC Machining Center

1. The worktable moves in a cross direction, the worktable moves in X and Z directions, and the headstock moves in Y direction. The headstock has two types of hanging and side hanging on the column. It is suitable for multi-process processing such as boring and milling of medium-sized and complex parts.

2. The spindle box moves in cross direction, the spindle box moves in X and Z directions, and the worktable moves in Y direction. It is suitable for multi-process processing such as boring and milling of small and medium-sized parts.

3. The spindle box is hung on the side and the column, and the spindle box moves in the Y and Z directions. This layout is similar to the planer type horizontal milling and boring machine, and the worktable moves in the X direction. It is suitable for multi-process processing such as boring and milling of medium-sized parts.

Mobile column type CNC machining center

1. Planer type, the bed is T-shaped, the worktable moves in the X direction on the front bed, and the column moves in the Z direction on the back bed. The spindle box has two types of hanging and side hanging on the column for Y-direction movement. It is suitable for multi-process processing such as boring and milling of medium and large parts, especially long parts.

2. Column cross movement type, the column moves in Z and U (parallel to the X direction), the headstock moves in the Y direction on the column, and the worktable moves in the X direction on the front bed. It is suitable for multi-process processing such as boring and milling of medium-sized and complex parts.

3. For spindle ram feed type, the spindle box moves in the Y direction on the column, and the spindle ram moves in the Z direction. The column moves in the X direction. The table is fixed or equipped with a rotary table. It can be equipped with multiple worktables, which is suitable for processing small and medium-sized multiple parts, and the time of workpiece loading and unloading and cutting can be overlapped.

The difference between horizontal CNC machining center and vertical CNC machining center

1. Workbench

The workbench of the vertical CNC machining center is generally a T-slot workbench with a cross slide structure. There are two sets of kinematic mechanisms responsible for the movement of the workbench in the direction perpendicular to each other. above.

The workbench of the horizontal CNC machining center only moves in the X or Y direction. The form of the workbench is generally a rotary workbench with dot matrix screw holes. It is relatively easy to choose an exchangeable double workbench.

2. Spindle

The vertical CNC machining center refers to the machining center with the main shaft in a vertical state, and the horizontal CNC machining center refers to the machining center with the main shaft in a horizontal state.

3. Processing object

The vertical CNC machining center is limited by the height of the column and the tool changer. It cannot process parts that are too high. It is suitable for processing discs, sleeves, and plate parts. The processed workpieces are relatively small in size. Angle head or CNC turntable. If a rotary table rotating along the horizontal axis is installed on the workbench, it can be used to process spiral parts.

The horizontal CNC machining center can complete the processing of the other four surfaces except the mounting surface and the top surface after one clamping. It is most suitable for processing box-type parts. After installing the angle head, it can realize pentahedron processing.

4. Column

The column of the vertical CNC machining center generally does not move, and it is generally made as thick as possible in order to pursue rigidity. There are also moving column vertical machining centers. The workbench of the moving column vertical machining center only moves in the X or Y direction, and the column will move in the Y or X direction accordingly. This design method has a large power requirement for the driving motor of the column. .

The column of the horizontal CNC machining center must be a moving column type. The column of the positive T-shaped horizontal machining center moves along the X direction, and the inverted T-shaped horizontal machining center column moves along the Z direction. The structure of the mobile column requires that the column must be as light and light as possible under the premise of satisfying the rigidity. Foreign machine tools often use steel plate welded structures to solve this problem.

5. Chip removal

When the vertical CNC machining center is processing the cavity or the concave surface, the chips are not easy to discharge. In severe cases, the tool will be damaged, the machined surface will be damaged, and the smooth progress of the processing will be affected.

The horizontal CNC machining center is easy to remove chips during machining, and the machining conditions are relatively ideal.

6. Control

The vertical CNC machining center is easy to clamp, easy to operate, easy to observe the processing situation, and easy to debug the program.

The workpieces processed by horizontal CNC machining centers are generally relatively large, difficult to clamp, difficult to monitor the processing process, and relatively difficult to operate and debug.