Handling and installation of CNC machining center

Handling the packaged CNC machining center

When hoisting the packing box with a lifting machine, the steel rope should be put on according to the mark on the packing box; when using a forklift, pay attention to the center of gravity of the packing box should be close to the forklift, and the bottom or side of the box should not be impacted or violently damaged during handling and unloading. Under no circumstances should the packing box be tilted excessively; when using the roller bar to move the packing box on the slope, the slope should not exceed 15°.

Open the packing box of the CNC machining center

After unpacking, first check the external condition of the CNC machining center, and check the accessories, tools and documents according to the packing list.

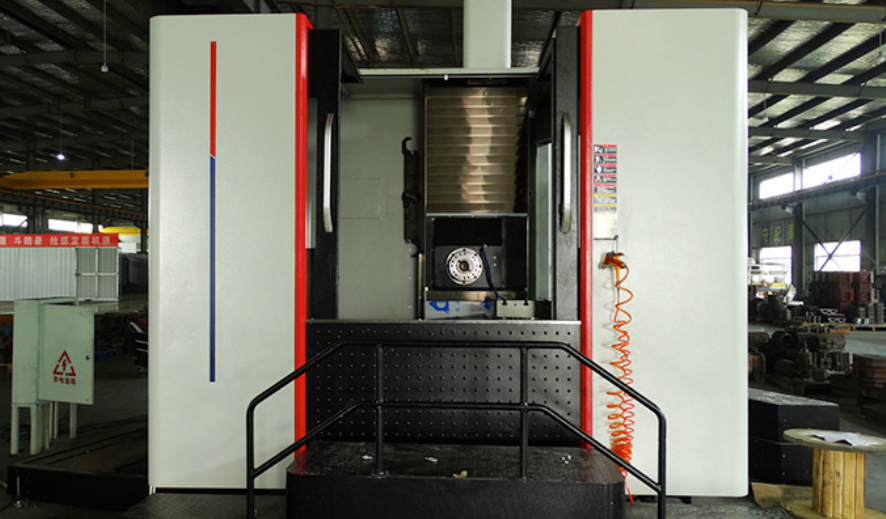

Handling Unpackaged CNC Machining Centers

The total weight of the CNC machining center is about 12 tons, and the main machine, tool magazine and full protective cover are hoisted as a whole.

Pay attention when lifting the CNC machining center:

1. Do not subject the main engine, electrical control cabinet, etc. to any impact or vibration during the handling and lifting of the CNC machining center;

2. Check the fastening condition of each part of the CNC machining center before handling;

3. The lifting load of the crane or the handling load of the forklift should be greater than 15000kg;

4. The main shaft moves to the lowest position, the worktable is in the middle of the stroke, and the column is in the rearmost position, and is fixed with a connecting plate;

5. Drain the liquid in the fuel tank and cooling tank;

6. Check whether the hoisting wire rope is firm and whether the length is appropriate, and use a suitable hoist if necessary;

7. Use eyebolts at the base and lower saddle, and remove the top cover of the full protective cover to let the steel cable pass through;

8. When hoisting, the steel cable cannot touch the weak link of the CNC machining center, and the contact surface between the CNC machining center and the steel cable is lined with an appropriate cushion to avoid scratching the painted surface;

9. Do not let the steel cable squeeze oil pipes, air pipes, cables, NC devices, electric cabinets, hydraulic components, etc.;

Install CNC machining center

CNC machining centers are prohibited from being placed in the following places:

1. Places exposed to direct sunlight, near heat sources or where the temperature changes greatly,

If possible, it should be installed in a constant temperature factory building;

2. Places with high humidity around;

3. Places with high dust concentration;

4. Near the source of the earthquake;

5. Where the foundation is weak;

6. Places close to high-voltage lines.

Installation of CNC machining center

The quality of the installation of the CNC machining center directly affects its life and machining accuracy. If the CNC machining center is not installed correctly, even if the machining accuracy of the guide rail is very high, it is difficult to achieve the expected purpose. In order to avoid the adverse effects of bad installation on the CNC machining center and make the CNC machining center achieve its proper accuracy, please follow the foundation diagram of the CNC machining center and follow the steps below to install the foundation diagram.

Technical requirements for foundation installation of CNC machining center

1. The foundation thickness is not less than 1000mm, and the foundation concrete grade is 250 (reinforced concrete).

2. The bearing capacity of the foundation shall not be less than 8/m 2 , and a block test shall be done.

3. After the foundation is poured, there must be no cavity inside or a cavity connected to the foundation range.

4. The surface of the foundation must be flattened, without any unevenness, and coated with anti-corrosion and waterproof paint (model PN-103). After the paint is applied, it must be maintained for one week before it can be used. The paint can be used with other types of products with the same performance.

5. The hydraulic oil tank, cooling box, spindle transformer, electric box and other accessories of the CNC machining center should be placed within the scope of the foundation according to the position shown in the diagram.

6. There must be a vibration isolation groove of 3620mm×3120mm around the CNC machining center, 80mm wide and 200mm deep, and filled with soft materials.

7. Under the foundation surface, double-layer staggered steel mesh of φ12~φ18 with a spacing of 200~300mm should be used. The distance between the upper layer of steel mesh and the upper surface should be greater than 150mm, and the distance between the lower layer of steel mesh and the lower surface should be greater than 150mm. Class and Class II steel bars.

8. A 150mm thick layer of C15 coarse sandstone concrete should be laid under the foundation concrete of the CNC machining center in the loess layer and compacted. If the groundwater level is high or the foundation is soft, refer to the "Industrial Comply with the provisions of TJ7-74 of Code for Design of Foundations of Civil Buildings.

CNC machining center installation steps

1. Move the CNC machining center to be installed to its installation site;

2. Drop the CNC machining center, adjust the adjusting screw of the pad iron of the CNC machining center, and level the CNC machining center;

3. Put the hydraulic box and cooling box of the CNC machining center in the correct position according to the diagram, and connect the pipelines;

4. Install the parts removed from the main engine during lifting and transportation, and remove the transport connecting plates of the saddle, column and headstock;

clean up

After the CNC machining center is installed, the dust on the surface of the CNC machining center should be cleaned first, and then the anti-rust oil on the exposed surface of the CNC machining center should be wiped clean with a kerosene cloth.

CNC machining center power connection

battery capacity

Where the CNC machining center is installed, the power supply capacity is sufficient and stable, otherwise, the power supply capacity is insufficient or the voltage changes greatly, which will have an unexpected impact on various functions of the CNC machining center, reduce the life of various electrical components, and may also cause safety issues. ACCIDENT. Therefore, please pay attention to the capacity of the power supply. The total installed capacity of this CNC machining center is 50KVA.

Check power phase sequence

The phase sequence of the total power supply should be the same as that stipulated in this CNC machining center. Otherwise, if the NC device is powered on, the CNC machining center will malfunction, the fuse will blow, and even cause a safety accident. Therefore, the phase sequence of the total power supply must be checked.

Check servo transformer and spindle transformer

When leaving the factory, the output terminals of the transformer are connected according to the needs, and the output terminals can be different from the connection method when leaving the factory according to the actual situation. If the transformer is improperly connected to the power supply, the electrical components of the CNC machining center will be in danger of burning out. Please refer to the "Instruction Manual (Electrical Part)" and relevant information for careful inspection.

! Notice!

1. If the voltage is unstable, please install a voltage stabilizer.

2. Keep the inside of the electrical box dry.

3. When connecting the power supply, all power switches must be turned off.

4. The ground wire must be connected.

Trial run of CNC machining center

The operator first carefully reads the instruction manual (mechanical and electrical parts), CNC machining center CNC system operation manual, servo unit, servo motor instruction manual and other materials, and operates manually, then automatically, and sequentially according to the relevant operation methods and sequences.

After the power supply is connected, you must check the operation of each part of the CNC machining center before you can work.