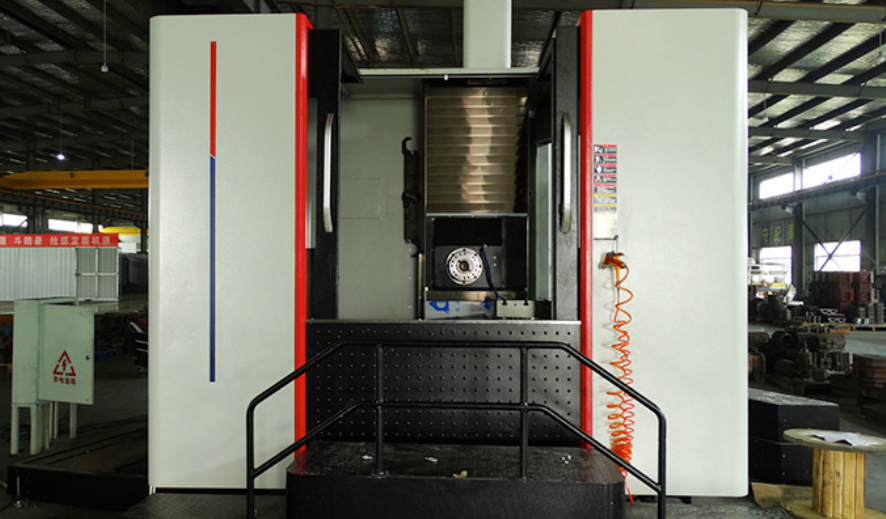

What is a vertical CNC machining center

Vertical CNC machining center is a kind of high precision and high efficiency machine tool, which is widely used in metal processing, mold manufacturing, aerospace, automobile manufacturing and other fields. It has a vertical layout of tables and tools, as well as a computer control system, capable of automatically performing a variety of machining operations. This paper will introduce the structure, working principle, application field and future development trend of vertical CNC machining center in detail.

A vertical CNC machining center usually consists of the following main components

1. Machine base: Supports an important part of the entire machine tool, usually made of cast iron to provide stability and rigidity.

2. Workbench: The workpiece is clamped on the workbench, and the workbench can be moved along the X, Y and Z axes to achieve multi-axis machining. The table usually has rotation and tilt functions to accommodate different processing needs.

3. Spindle head: The spindle head is installed on the beam of the machine tool and is responsible for supporting and rotating the tool. It can be rotated at high speed in order to cut the workpiece.

4. Knife store: Knife store is the storage and replacement location of knives. Different types of tools can be automatically changed according to the processing requirements.

5. Numerical control system: The numerical control system is the brain of the machine tool, which receives instructions from the operator or computer aided design (CAD) software and converts them into motion control signals to control the movement of the table and spindle head.

Working principle

1. Operators use CAD/CAM software to create digital design drawings of parts and generate corresponding G-code programs.

2. The G code program is uploaded to the numerical control system, which interprets the program and controls the movement of the workbench and the spindle head.

3. The workpiece is clamped on the workbench, and the spindle head is equipped with the required tool to start the automatic processing process.

4. The CNC system monitors the tool position and workpiece position to ensure the accuracy and stability of the cutting process.

5. Once the processing is complete, the workbench takes the workpiece out of the machine.

Application field

Vertical CNC machining centers have a wide range of applications in a variety of fields, including but not limited to:

1. Aerospace: Used to manufacture aircraft parts, rocket engine parts, etc.

2. Automobile manufacturing: production of automobile engine, transmission, chassis components, etc.

3. Mold manufacturing: Manufacturing plastic injection molding molds, die casting molds and precision molds.

4. Medical equipment: Manufacturing medical equipment parts, such as artificial joints, surgical tools, etc.

5. Shipbuilding: Manufacture of components for large ships.

6. Electronic manufacturing: Manufacturing printed circuit boards (PCBS) and microelectronic parts.

7. General machinery manufacturing: used to process a variety of metal and non-metal materials and produce a variety of products.

Future development trend

With the continuous progress of technology, vertical CNC machining centers are also developing. Here are some possible future trends:

1. Intelligence and automation: The machining center will be more intelligent, with automatic tool replacement, automatic workpiece clamping and automatic detection functions.

2. High-speed cutting: will further improve the rotation speed and feed speed of the spindle head to achieve higher production efficiency.

3. Augmented Reality: Augmented reality-based maintenance and operational support systems may emerge to improve the availability of machine tools.

4. Green manufacturing: Develop more environmentally friendly coolants and cutting fluids to reduce environmental impact.

5.3D Printing integration: Combined with traditional cutting technology for faster prototyping and production.

6. Larger work area: Larger vertical machining centers will be developed to accommodate larger size workpieces.

In summary, vertical CNC machining centers play a vital role in the manufacturing industry, and as technology continues to evolve, they will continue to improve production efficiency, precision and innovation to meet changing manufacturing needs.